Our Process: Supercritical CO2 Extraction

How We Get the Purest Extracts and Ingredients

At United Bioscience, we use supercritical CO2 extraction to get the best compounds from various raw materials, like plants and herbs. This method is known for its efficiency, precision, and eco-friendliness, making it a top choice in food, cosmetics, and pharmaceuticals. Let’s dive into what this process is, how supercritical CO2 extraction benefits you, and where to use ScCO2 extracts.

What is Supercritical CO2 Extraction?

Supercritical CO2 extraction uses carbon dioxide (CO2) at high temperatures and pressures to extract valuable compounds. When CO2 is in its supercritical state, it behaves like both a liquid and a gas. This unique state allows CO2 to dissolve and extract a wide range of compounds, including oils and waxes.

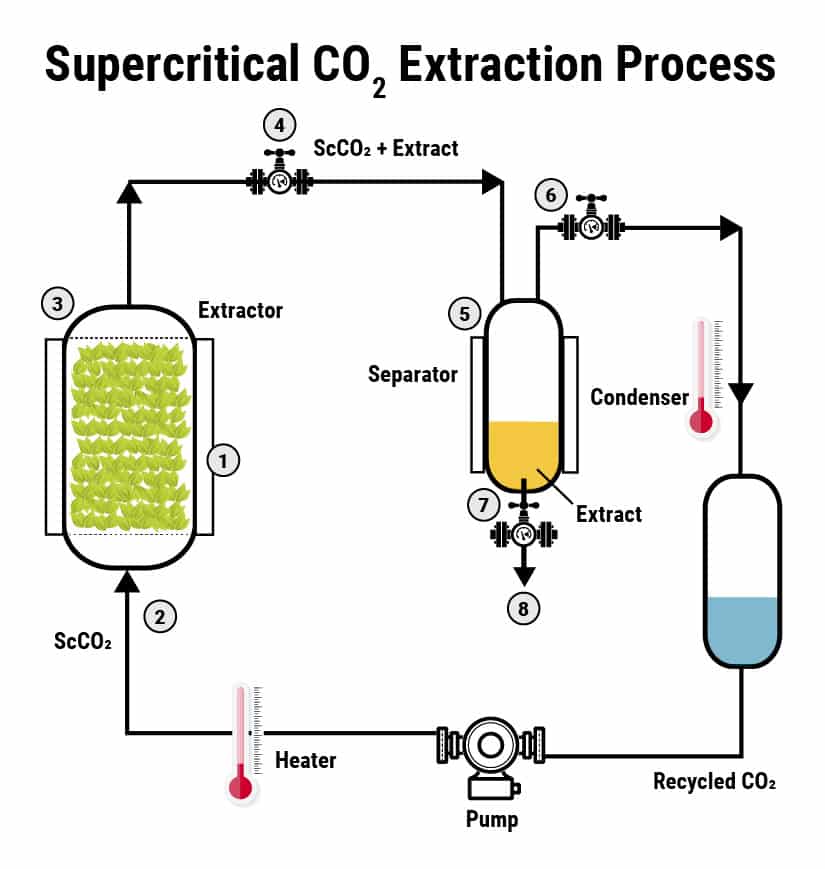

- Extractor chamber is filled with biomass.

- The pump forces supercritical CO2 (ScCO2) into the extractor chamber.

- The ScCO2 acts as a solvent, dissolving the natural or botanical oils it contains.

- The ScCO2 carries the oil past a pressure-regulating valve into a separator.

- In the separator, the pressure is lowered, and the extracted oil precipitates from the CO2.

- The subcritical liquid CO2 separates from the oil and is routed to the CO2 recycler to be used again in a closed-loop system.

- The botanical oil, waxes, and resins descend in the separator where they are captured.

- The resulting oil is processed further into various products, free of any solvents.

ScCO2 Extraction Steps

Prepare the Raw Material

First, we clean and grind the raw material into a fine powder. This increases the surface area for extraction, making the process more efficient.

Load the Extraction Vessel

Next, we load the prepared material into the high-pressure extraction vessel.

Pressurize with CO2

We then pressurize and heat the CO2 until it reaches its supercritical state. This supercritical CO2 is pumped into the extraction vessel, where it penetrates the raw material and dissolves the target compounds.

Separation and Collection

The CO2 carrying the dissolved compounds moves to a separator vessel. Here, we reduce the pressure, causing CO2 to revert to its gaseous state and separate from the extracted compounds. We then collect the pure compounds for further processing.

Recycle the CO2

To minimize waste, we recycle the CO2 back into the system. This closed-loop system not only saves costs but it is also sustainable.

Why Supercritical CO2 Extracts?

High Purity and Quality

We produce high-purity extracts with minimal contaminants. This ensures that you get the best quality for your products, whether they’re in the food, pharmaceutical, or cosmetic industries.

Eco-Friendly

Using CO2 as a solvent is non-toxic, non-flammable, and recyclable. Our process generates minimal waste and avoids harmful chemicals, making it environmentally sustainable.

Selective Extraction

We can fine-tune the temperature and pressure to selectively extract specific compounds. This precision allows us to create tailored extracts for your unique needs.

Preservation of Bioactive Compounds

Our low operating temperatures preserve the natural state of bioactive compounds, maintaining their effectiveness and potency.

Safe and Efficient

Our process is safe and efficient, with a closed-loop system that reduces the risk of exposure to harmful substances. Plus, it’s faster than traditional methods.

Versatility

Supercritical CO2 extraction works with a wide range of raw materials, making it versatile and adaptable to different products.

Where We Use ScCO2 Extraction

Nutraceuticals and Supplements

We extract essential oils, vitamins, and other bioactive compounds for health supplements.

Pharmaceuticals

We isolate active pharmaceutical ingredients and other medicinal compounds.

Food and Beverages

We create flavors, fragrances, and natural colorants for food and beverage products.

Cosmetics and Personal Care

We extract natural ingredients for skincare, haircare, and other personal care products.

Environmental Applications

We also use it for the remediation of contaminated soils and extraction of valuable compounds from waste materials.

Looking for Premium Ingredients?

We provide brands with premium, bioavailable ingredients crafted through clean extraction methods and cutting-edge formulation technology.